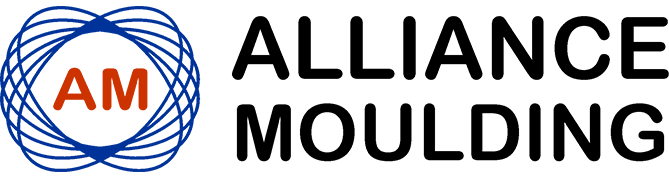

Nexus Conveyor Covers

- Nexus Conveyor Covers are engineered to survive tough mining environments

- The unique design of the conveyor roller cover drives economies in installation and ongoing maintenance

- There are flexible options to adapt existing Nexus Conveyor Covers to evolving mine site conditions by adding doors, screens or dust vents

- Australian owned and manufactured

Product Details

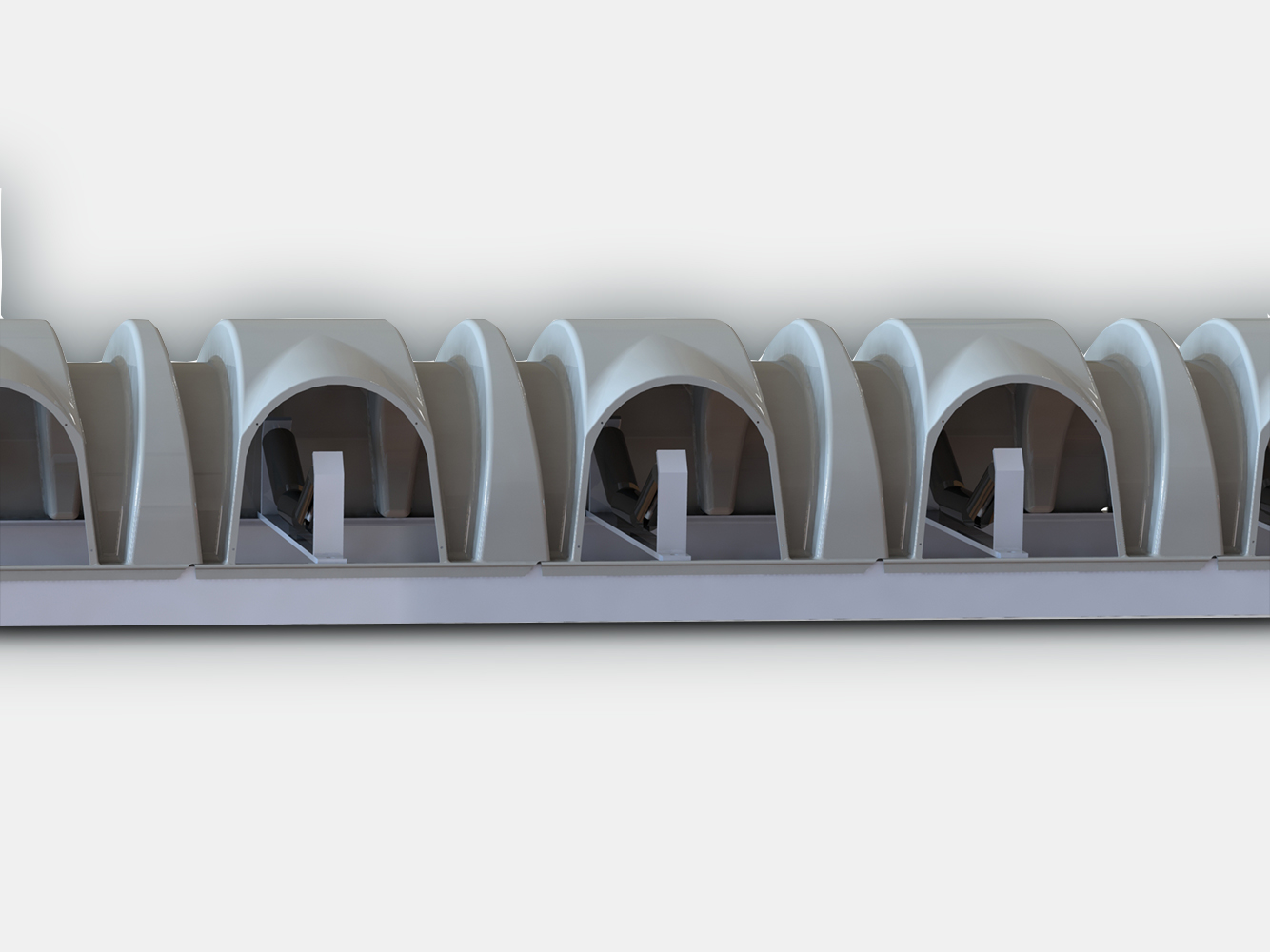

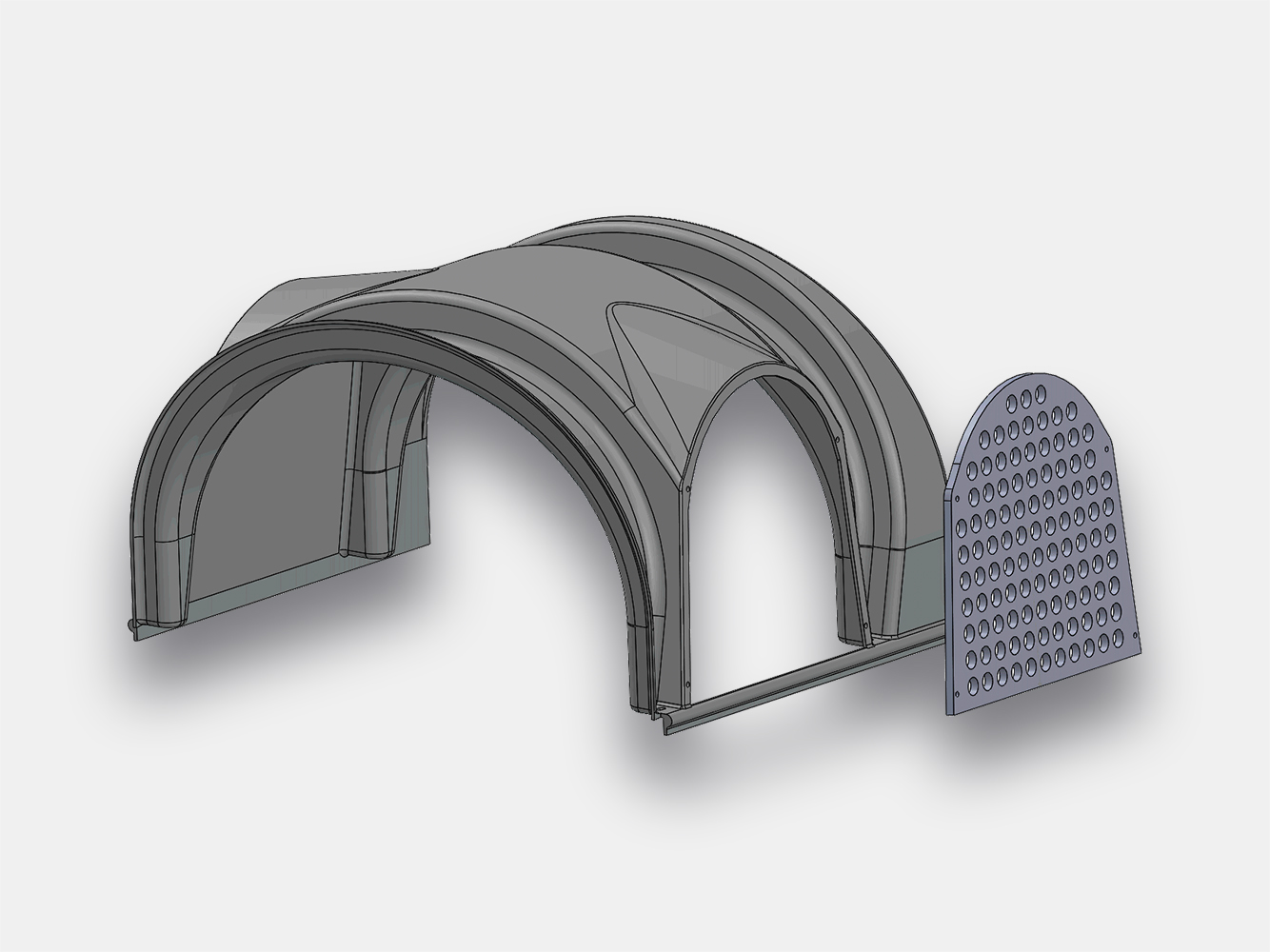

- The new Nexus Conveyor plastic cover was designed in conjunction with industry experts to meet or exceed industry expectations for performance, accessibility, flexibility and cost

- It is a tough, rotomoulded polyethylene conveyor cover that is durable, easy to manoeuvre and install on site. The material is UV treated, and unlike galvanised covers will not rust, providing years of protection

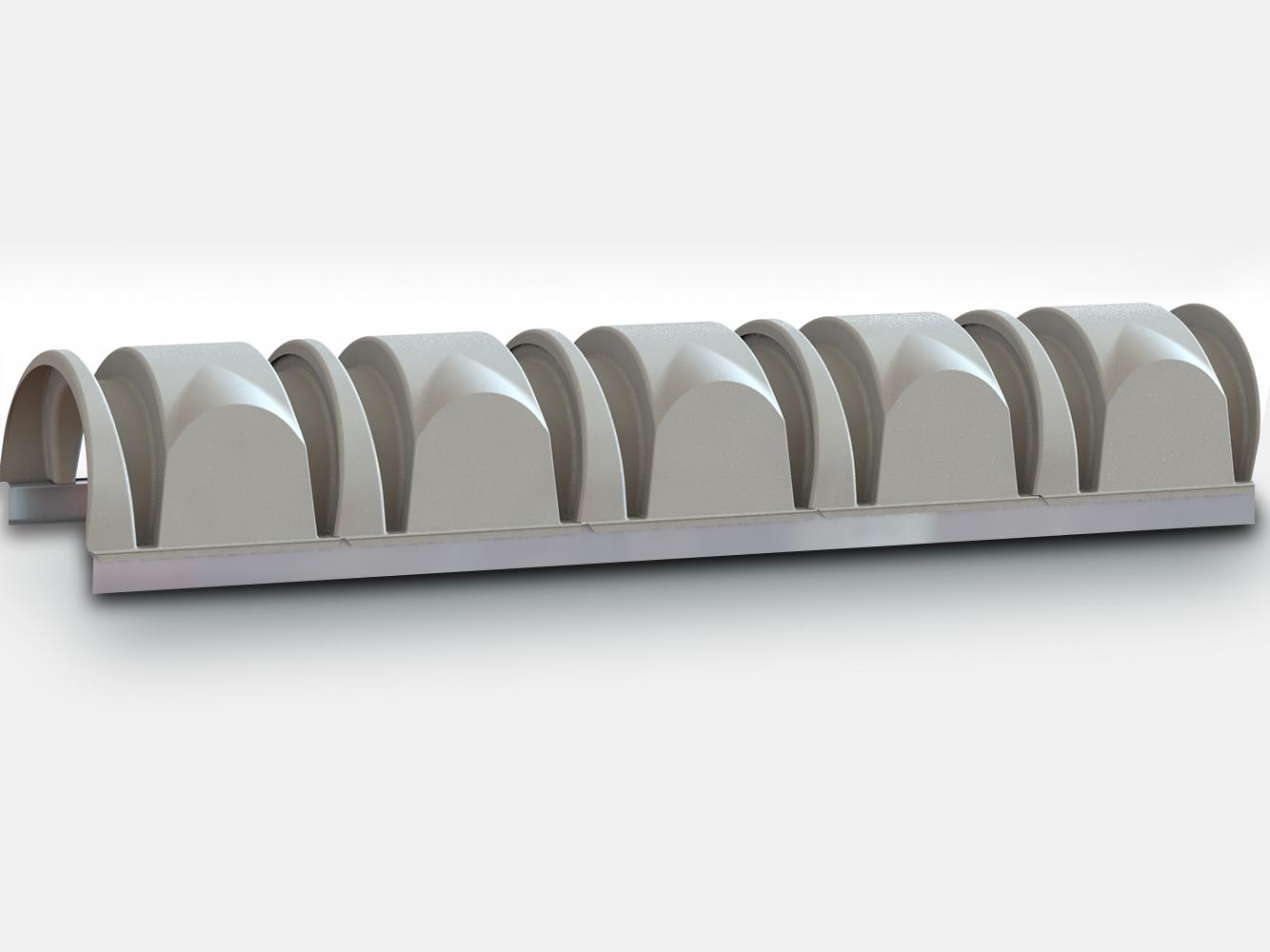

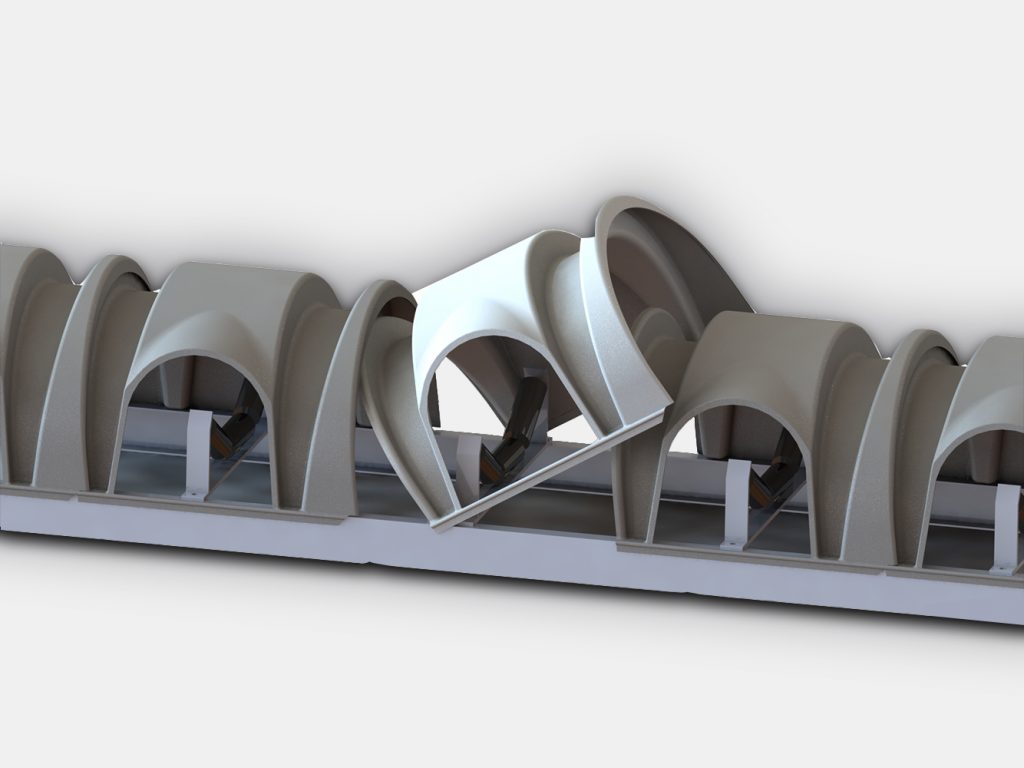

- The unique design allows any single roller cover to be removed by itself. There is no need to remove adjacent roller cover just to clear the one you want. Various size spans are available

- Installation is simple and requires no additional steel framework, providing good cost savings for any project

- The speed and ease of handling the conveyor cover creates a lower cost factor for any inspections or ongoing maintenance

- Nexus Conveyor Roller Covers allow access to rollers for maintenance without removal of roller cover

- Independently Engineered to withstand cyclonic conditions

Nexus Conveyor covers provide a versatile solution for any application: Fully enclosed, open one or both sides, dust extraction ports.

The unique design also offers many solutions for retrofitting options for existing installed Nexus covers, should the conditions on-site change. There are options for retrofitting doors, mesh screens, or dust covers with extraction vents. No need to replace the full cover, the Nexus Conveyor Cover allows easy retrofit on site.