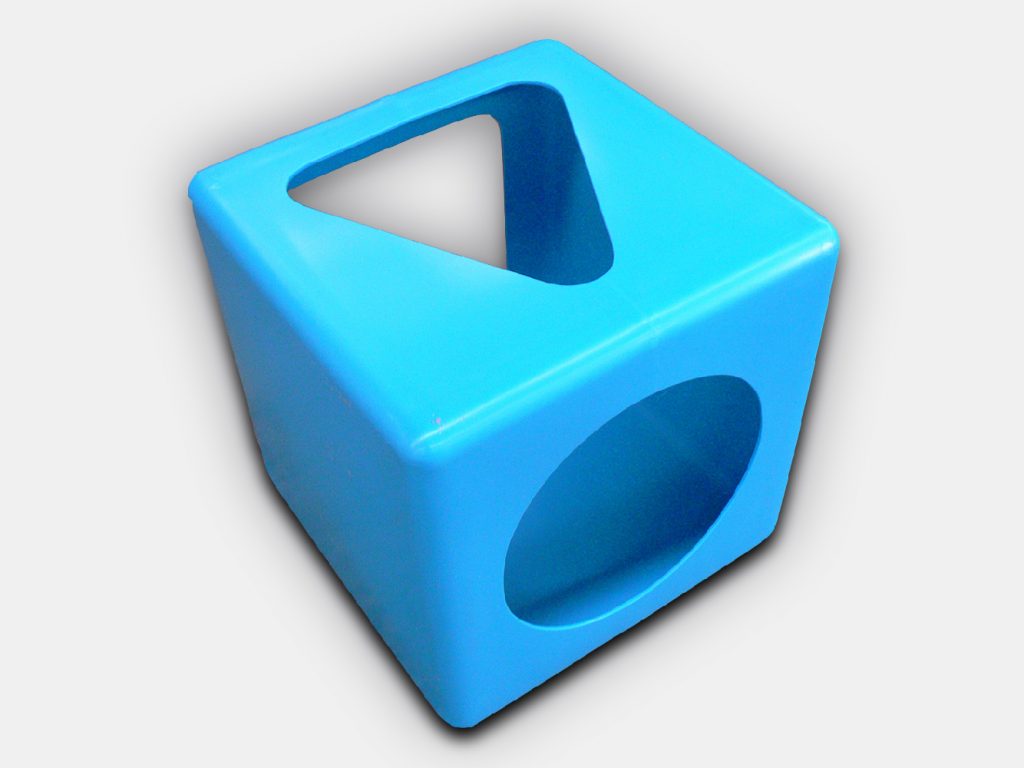

Rotomoulding is a complex process, and the success of the moulded product will depend on many factors including :

- the design,

- the mould,

- resin selection,

- cook and cool process,

- the knowledge and experience of the operators.

The reputation of Alliance Moulding is second to none. An increasing number of clients are finding that we can, where other moulders cannot.

Over the years we have developed a reputation for being the ‘go-to Company’ for custom moulding, and we have been able to help many of our clients turn their problem moulding into successful outcomes. Alliance Moulding will provide good quality service and products at competitive prices. We are customer-oriented and our main aim is fulfilling your needs.

It is our knowledge and experience, attention to detail, precision moulding and production capabilities that will enable us to mould your product to a high quality every time.

Many clients have to meet critical dimensions and need consistency in strength and thickness for warranty work, or need to meet high aesthetic standards with graphics and special surface finishes. We can mould parts which contain inserts, threads, moulded in graphics and complex shapes. Testing is also part of our daily routine.

Alliance Moulding will give you the peace of mind that your product quality will meet your demands, every time. Every care is taken with client moulds to ensure they remain in good condition and minor maintenance is done on an ongoing basis.

Alliance has worked with a number of manufacturing companies who are following the trend to move from steel or alloy housings for machinery parts to a rotationally moulded plastic alternative. The switch gives our clients significant cost savings, timely supply and solves many internal production issues.

We have the manufacturing capacity to deal with both high volume runs and complex unique product ranges.

If you currently have or would like to develop a hollow plastic part we would like to help. We have a full 3D capacity to allow you to see your product prior to prototyping.